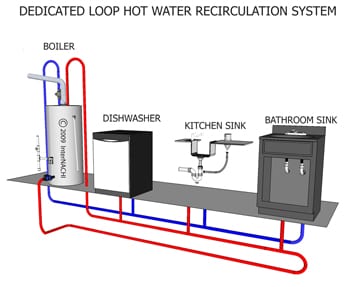

- dedicated loop: The circulation pump for this system is mounted on a pipe connected to the water heater tank down low. This is the cooler side of the loop, or the return.

The hot water pipe is installed in a loop throughout the home, passing near each plumbing fixture. At each fixture, a short pipe connects the loop to the hot water valve. Because hot water is constantly circulating through the hot water loop, any time a valve is opened, it takes only a fraction of a second for hot water to reach the valve.

- integrated loop: This system is typically used on retrofits but may also be installed on new construction. It consists of a pump installed under the plumbing fixture farthest from the water heater. The pump contains a sensor which switches the pump on when water temperature drops below 85° F, and switches it off when water temperature reaches 95° F. Newer pumps are adjustable from 77° to 104° F.In this system, hot water is re-circulated intermittently. Hot water is returned to the water heater via the cold water pipes. This raises the temperature of the cold water slightly, but it returns to the usual cold temperature in a short time.

Activation

Hot water recirculation systems are most commonly activated by either a thermostat or a timer. Systems that use a thermostat or timer automatically turn the pump on whenever the water temperature drops below a set point, or when the timer reaches a certain setting. These systems ensure that hot water is always available at the faucet.

Do they really save energy and water?

Regardless of whether they are controlled manually or automatically, recirculation systems reduce the amount of water that goes down the drain while the homeowner waits for the desired temperature. This fact allows for the following three advantages over conventional water distribution systems:

- They save time. Recirculating systems deliver hot water to faucets quickly, adding convenience for the homeowner.

- They conserve water. According to statistics from the U.S. Department of Energy and the U.S. Census Bureau, between 400 billion and 1.3 trillion gallons of water (or close to 2 million Olympic-sized swimming pools) are wasted nationally by households per year while waiting for water to heat up.

- They limit municipal energy waste. The DOE estimates that 800 to 1,600 kilowatt-hours per year are used to treat and pump the water to households that will eventually be wasted while the occupant waits for tap water to warm to the desired temperature.

If recirculation systems pump continuously, however, they have the potential to use significantly more energy. For a modest-sized pump, this might be 400 to 800 KWH a year if the pump runs all the time. Also, heat loss from the pipes can be significant if the hot water pipes are poorly insulated. This will result in the hot water heater running more. This added heat may be a benefit in the winter, but heat loss may add heat to the house in the summer and may result in higher bills for use of air conditioning.

Rebates

Some jurisdictions, particularly in areas where water is scarce, offer rebates on the purchase and installation of hot water recirculation systems. The cities of Santa Fe and Albuquerque, New Mexico, for instance, offer a $100 rebate for homeowners who purchase a hot water recirculation system. The city of Scottsdale, Arizona, offers up to $200 for residential property owners who install theses systems, although they must comply with UL-product and installation standards. Some systems may not comply with efficiency standards set by these municipalities.

Availability and Cost

Hot water recirculation systems are available nationwide from manufacturers, distributors, plumbing wholesale supply warehouses, and at selected retail home stores. The initial cost of dedicated systems may prevent some homeowners from installing these systems, as they require the purchase and installation of a pump and a large amount of piping. Integrated systems, by contrast, require only a pump and fittings. Energy savings will vary, depending on the design of the plumbing system, method of control and operation, and homeowner use. The system is easily installed and costs less than $400.

Inspection Considerations

These systems all require an in-line air valve and shut-off valve. Other requirements will vary with the installation’s configuration, but may include a check valve and an additional shut-off valve. The pump may be connected to a sensor with high and low temperature limits so that the pump circulates water through the loop only when the sensor calls for it.

Inspections should be limited to the system’s proper operation.

From Hot Water Recirculation Systems – InterNACHI http://www.nachi.org/hot-water-recirculation-systems.htm#ixzz34y8GNbkD