Water damage is a homeowner’s nightmare, often leading to costly repairs and health hazards if left unchecked. Identifying the early signs of water damage is crucial for maintaining your home’s structural integrity and safety. This blog post will explore the top 10 signs of water damage in homes that every homeowner should know to take proactive measures and prevent extensive damage.

Musty Odors

A persistent musty odor is one of the most noticeable signs of water damage. Detecting a damp, moldy smell in your home could indicate hidden water leaks or moisture buildup behind walls, under floors, or in the ceiling.

Stained Walls or Ceilings

Water stains on walls or ceilings are telltale signs of water infiltration. These stains may appear as discolored patches, streaks, or rings, indicating past or ongoing water damage. Be sure to investigate the source of the staining to prevent further deterioration.

Peeling or Bubbling Paint

Moisture trapped beneath the surface can cause paint to bubble, blister, or peel. If you notice paint flaking off or bubbling in certain areas of your walls or ceilings, it strongly indicates water damage underneath the paint layers.

Warped or Buckled Flooring

Water seeping into flooring materials like hardwood, laminate, or vinyl can cause them to warp, buckle, or swell. Check for uneven or raised floor areas, especially in areas prone to water exposure, such as kitchens, bathrooms, or basements.

Sagging or Deteriorating Drywall

Excess moisture can compromise the integrity of drywall, leading to sagging, softening, or crumbling. Inspect your walls for signs of deterioration, including sagging patches, soft spots, or visible mold growth indicative of water damage.

Mold and Mildew Growth

Mold and mildew thrive in damp, humid environments, making them common water damage indicators. Look for black spots, fuzzy growth, or musty odors, particularly in areas with poor ventilation or high moisture levels.

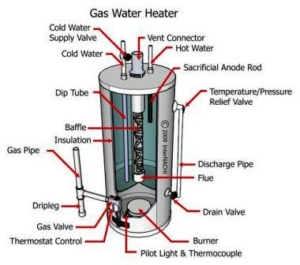

Corroded Pipes or Plumbing Fixtures

Leaking pipes or plumbing fixtures can cause corrosion and rust buildup over time. Check under sinks, behind toilets, and around water heaters for signs of water stains, corrosion, or rust, as these may signal hidden leaks.

Water Meter Spikes

A sudden increase in your water bill without a corresponding increase in usage could indicate a hidden water leak. Monitor your water meter regularly for unexpected spikes or fluctuations, which may suggest an undetected plumbing issue.

Damp or Moldy Basement

Basements are vulnerable to water intrusion due to their below-ground location and susceptibility to flooding. Look for dampness, mold growth, or efflorescence (white, powdery residue) on basement walls, as these are signs of moisture penetration.

Moldy or Rotten Smell in Cabinets or Closets

Hidden water leaks behind cabinets or inside closets can go unnoticed for extended periods, leading to mold growth and structural damage. If you detect a foul odor or musty smell from cabinets or cupboards, immediately investigate for signs of water damage.

Conclusion

Early water damage detection is critical to mitigating its impact and preventing costly repairs. By familiarizing yourself with the top 10 signs of water damage outlined in this blog post, you can proactively safeguard your home and address any issues before they escalate. Remember to conduct regular inspections and seek professional assistance if you suspect water damage beyond your expertise. With vigilance and timely intervention, you can keep your home safe, dry, and free from the detrimental effects of water damage.